Product Characteristics:

The bulletproof principle of Sinty UD fabric mainly has the following two aspects: on the one hand, it bounces the fragments formed by the fragmentation of the projectile body, and on the other hand, the bulletproof material dissipates the kinetic energy of the warhead.

Why choose Sinty high-performance UD fabric?

Sinty Fiber utilizes state of the art manufacturing technology and equipment combined with 9 patents on software control to ensure that technical and product quality exceed international standards. Employees are the company's most valuable assets. Sinty’s excellent R&D team guarantees customized requirements from design through production; promising quality control as well as after-sales services.

By cooperating with organizations both domestically as well as internationally, including elite high-tech equipment manufacturers in Europe and top universities in China, Sinty has developed a strong foundation for technological innovation, product enhancement, and talent training.

With over a decade of experience in serving 50 plus countries and 21 local provinces, Sinty Fiber’s production lines include products ranging from 30D to 3200D.

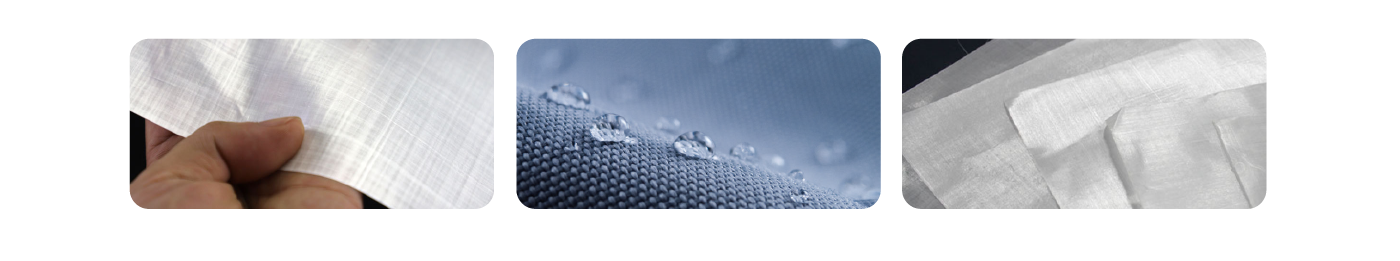

1) Good radiation and UV resistance.

2) Excellent resistance to acid, alkali and other chemical corrosion.

3) Smooth surface; low friction coefficient; not easy to fluff.

4) The elongation at break is 3.5%, and the bending fatigue resistance is much better than that of Kevlar.

5) Extremely high resistance to cutting and abrasion, while the heat stability is not good, and the melting point is above 135 ℃.

6) The density of the fiber is 0.97, which is much lower than other materials.

Product specifications:

Application Area:

* Bulletproof Material:Soft body armor, light weight bullet-proof helmet, bullet-proof armor plate; Anti-puncture and anti-cutting clothing; special anti-explosion facilities, etc.

* Medical Field: Plywood, bandages, artificial respirator, etc.

* Chemical Field: Three-dimensional horizontal storage tank, pipe, workstation, etc.

* Military Field: Protective armor for aircrafts, cars, large caliber artilleries, tank load wheels, etc.

* Other Fields: Reinforced precursor for construction and scabbard, etc.